Driving Uptime of Heavy-duty Fleets

Minimize vehicle breakdowns and optimize Total Cost of Ownership.

Top Maintenance Challenges That Fleet Managers Face

Poor vehicle health is a big problem for fleet owners driving up their Total Cost of Ownership (TCO) by $ 2.5 M across the fleet.

How Tensor Planet Helps

AI-driven predictive maintenance spots vehicle failures weeks before they occur, optimizes service schedules, and right-sizes fleets.

Value Unlocked For Customers

Tensor Planet offers 10X returns by saving an estimated $1.5 M annually per fleet with Predictive Insights.

01

$200 K

Annual savings by minimizing breakdowns and costly repairs.

02

$1.1 M

Annual savings by extending vehicle lifespan.

03

$100 K

Annual savings by reducing unnecessary spare vehicles.

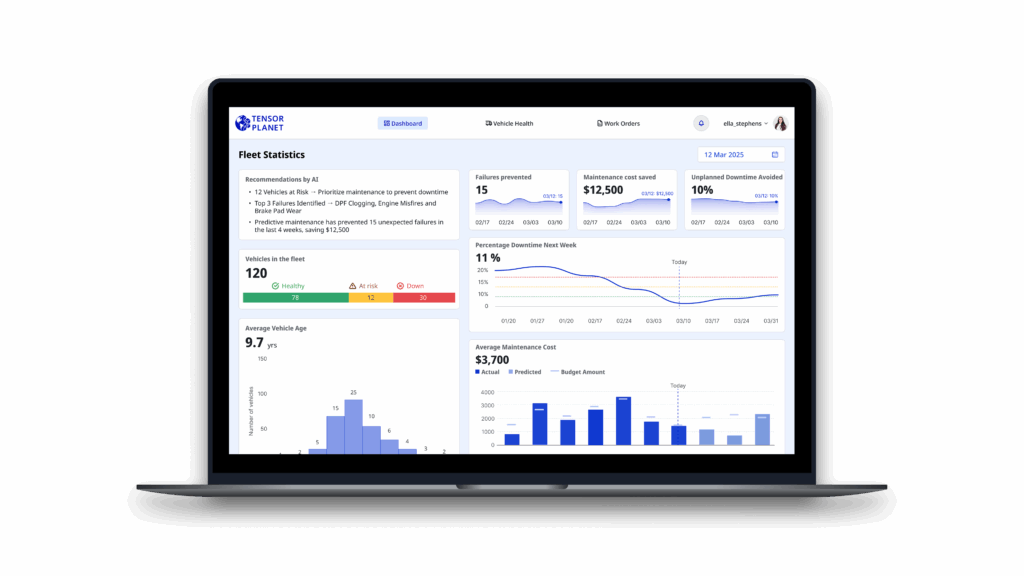

Accessible through all devices

Track fleet health scores, receive alerts, and schedule maintenance from anywhere.